Search

Home » Search

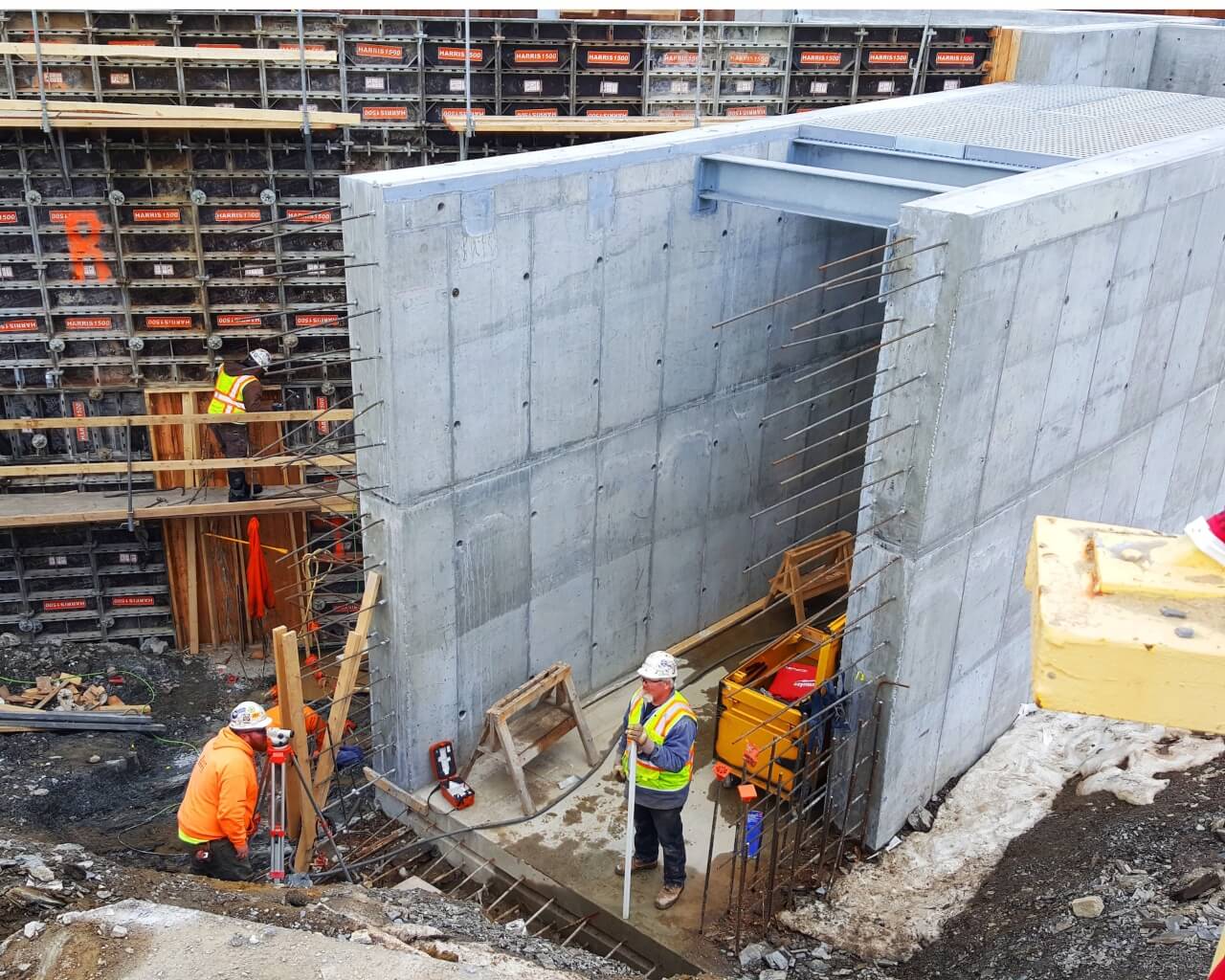

Starting July 5, 2016 Bancroft began construction of an 11-million-dollar upstream fish passage facility for Brookfield Renewable Power. The new fish passage is located on the east bank of the Kennebec river just downstream of the Hydro-Kennebec Dam which spans the river between the towns of Winslow and Waterville, Maine.

Bancroft Contracting served as general contractor for the project. We relied on subcontractors McGee Construction for site earthwork, HB Fleming for construction of an upstream cellular cofferdam, Maine Drilling and Blasting for line drilling and blasting ledge, and Rioux Electric for electrical work.

Aside from managing the subcontracted work, Bancroft provided skilled crews which self-performed the entire remaining scope of work, amounting to about 80% of the project. Bancroft crews constructed a downstream sheet-pile cofferdam, de-watered the worksite, installed 5,200 cubic yards of complex cast-in-place concrete structures, tied and installed 508,000 pounds of re-bar, 140 tons of structural steel, six mechanically operated gates, 550 linear feet of 4.5 and 5-foot diameter butt-welded attraction water piping, as well as the entire proprietary fish-lift system, with a wide array of miscellaneous metals including steel grating, stairs, and handrails.

Bancroft Contracting re-built 400 linear feet of the Number 4 Penstock at the Mill Hydro hydroelectric facility in Millinocket, Maine for Brookfield Power of Gatineau, Quebec. The Number 4 Penstock is one of six similar penstocks on the site, each feeding a generator/turbine pairing.

The Mill Hydro Penstock project required Bancroft Contracting to expose an existing 10-foot diameter underground steel penstock, cut two 25-foot openings in it, and then install a 9-foot diameter steel penstock inside it. Bancroft installed the new penstock by lowering short sections through the access openings and pulling the new penstock sections as far as 150 feet through the existing pipe. The project demanded precise positioning of the new penstock within the old one. Each section of new penstock material had to be exactly aligned and welded out completely in multiple passes. Finally, the void between the two penstocks had to be filled with flowable grout, the responsibility of subcontractor Knowles Industrial Services of Gorham, Maine.

The project involved complex heavy rigging challenges, placement of over a mile of full-penetration weld, and pumping of approximately 215 cubic yards of flowable grout.

Cost of the project was approximately $1.4 million. Project Manager for Brookfield Power was Max Upton, engineering was by Devine, Tarbell & Associates. Installation of flowable grout was subcontracted to Knowles Industrial Services. Bancroft Contracting Corporation served as general contractor, represented on site by Kent Lewin, Project Superintendent.

In just over 12 months, beginning October 2012, Bancroft Contracting Corporation constructed twin hydroelectric generating facilities on the Stillwater River in Penobscot County, Maine. The facilities were part of a groundbreaking regional negotiation balancing environmental concerns with the need for renewable energy generation. Bancroft crews worked through a brutal Maine winter to meet a critical schedule truncated from 18 months to 12 due to federal permitting delays.

Bancroft Contracting Corporation in conjunction with Kleinschmidt USA, designed and constructed a rubber bladder flashboard system for NextEra Energy on the Shawmut Dam at Shawmut Village on the Kennebec River. The finished design called for three separate 240-foot long rubber bladders, spanning the entire length of the dam crest.

The project required removal of an existing steel-pin and plywood flashboard system as well as approximately 155 cubic yards of existing concrete on the 750-foot long spillway of the Shawmut Dam. Bancroft Contracting crews installed approximately 1,500 cubic yards of replacement crest concrete, embedding bladder-system anchoring hardware as required. The project required construction of two 40-cubic-yard, 10-foot high concrete piers, separating the crest into three 240-foot sections to allow installation of the three bladders. Bancroft erected a pre-engineered steel control house, air pumps, associated controls and extensive stainless steel air-piping to allow operation of the new bladder system. Finally, Bancroft installed the three 250-foot long 4.3-foot high air-inflatable rubber bladders on the dam crest.

Project Manager for NextEra was Paul Plante, Bancroft Contracting Corporation was general contractor, represented by Project Manager Allan Howe, and on site by Superintendent Mario DeMillo. Engineering was by Kleinschmidt USA, represented by Steve Ruell.

Contribution to the Community

The Shawmut Dam crest renovations project makes its most important contribution to the community by increasing the efficiency of the NextEra Energy Shawmut Station as a source of clean hydroelectric power. Maine’s electric power needs are currently met in largest part by power generated from burning natural gas and imported oil. This project permits NextEra operators to control the crest height remotely and under any water conditions. This ability assures maximal utilization of available water flow even during and immediately following seasonal and other high-water events. Because of this project, the Shawmut Dam is a more efficient source of clean, locally produced electric power that lessens the community’s reliance on imported fossil fuels with their attendant carbon outputs, increasing cost, and potential availability issues.

The crest renovations also contribute significantly to safety of the site operators by allowing them to control dam crest height by the operation of remote controls, rather than by direct access to the crest itself.

Job Challenges & Innovation

Water control for the duration of the project presented one of the most difficult challenges. Frequent high water events on the Kennebec River prevented access to various work locations on the dam crest at unpredictable times. In order to maintain progress on the project, it was necessary to change work locations on the dam frequently, and to maintain a flexible approach to the construction plan.

Installation of crest concrete proved another challenge. Distance and site topography made it impossible to pump concrete to most locations along the 750-foot crest. Bancroft responded to this challenge by ordering seven-yard loads of concrete and transporting them to the dam crest by barge in 1-yard concrete hoppers. Bancroft crews then used a barge-mounted crane to place the concrete one yard at a time. The use of seven-yard loads of concrete allowed Bancroft crews to complete placements within the 1 ½ hour window allowed by the project specifications.

Environmental

The Shawmut Dam crest renovations project was carried to completion without adverse environmental impact. The project waste stream was contained and appropriately disposed. Impacts to water and air were minimal or non-existent.

The project has positive environmental impact in that it will permit this important Maine hydro site to produce clean, renewable electric energy at peak efficiency.

Response to Client Needs

Bancroft Contracting Corporation together with Kleinschmidt USA provided NextEra with a complete design-build crest renovation package. During the progress of the project, Bancroft engineered and installed a crest-mounted bulkhead that allowed Bancroft crews to work efficiently despite high-water levels. This bulkhead was a critical factor in allowing Bancroft to complete the project within the intended schedule.

Bancroft’s flexible approach to the construction schedule kept the crew productive during periods of high water and allowed Bancroft to complete the project on schedule.

Safety

Relying on workplace safety practices and the “zero accidents” culture developed and practiced over years at both NextEra Energy and Bancroft Contracting allowed Bancroft crews to complete this high-risk, two-year project with zero incidents and zero injuries. The Shawmut Dam Crest Renovation project began and ended with no daylight between owner and contractor with respect to the priority placed on worker safety.

Credit for this accomplishment belongs in several places: NextEra has always made it clear that production never takes precedence over safety on their projects. Project Manager Allan Howe and Superintendent Mario DeMillo provided effective safety leadership for the duration of the project. However, the lion’s share of the credit for this outstanding safety accomplishment goes to the Bancroft crew. These trained and seasoned construction professionals worked under demanding conditions without compromise to safe work practices, producing safety results for the Shawmut Dam project second to none in the industry.

Late in 2014 St. Croix Tissue LLC committed to install two new tissue production machines at its mill in Baileyville, Maine. Starting January 2015 Bancroft Contracting constructed building foundations and erected building structural steel for a 61,000 square-foot industrial building, 85 feet in height. Bancroft also constructed concrete foundations and machine-tracks for the two paper machines St. Croix installed in 2015 and 2016. Bancroft placed a total of 9,500 yards of complex cast-in-place concrete, 2,000 tons of structural steel, and a quarter-million pounds of rebar, much of it unprotected winter conditions.

In 2016 and 2017 Bancroft Contracting undertook significant upgrades to Green Mountain Power’s Weybridge Station in Weybridge, Vermont. Scope of the project included significant upgrades to the intake gate structures, trash racks, and forebay. In addition Bancroft mechanical crews installed two new horizontal turbines in the existing powerhouse.

Bancroft Contracting’s Mechanical Trades are performed on industrial and commercial construction sites. The positions require heavy physical work under all environmental conditions. Good physical conditioning is important to success in the positions. Regardless of prior formal training or experience, an employee must demonstrate on the job, the ability to carry out or to quickly learn and competently execute, all essential functions of their position. These positions require travel within New England — either a valid driver’s license and reliable vehicle, or a practical alternative plan for getting to the jobsite, is a requirement of the job. A typical schedule is Monday through Friday, 6:30 a.m. to 5:00 p.m., with opportunities for additional work on weekends.

—

Positions Available

Construction Worker (Entry-Level)

Has limited to no experience on construction worksites, but understands and has some experience in the use of most basic hand tools and hand power tools. Quickly learns the use of basic gasoline and air-powered tools including rock drills, jackhammers, rivet-busters, chainsaws, cut-off saws and others. The Construction Worker learns to work effectively and efficiently at tasks such as shoveling, drilling, jack hammering, carrying, jobsite housekeeping, running errands, moving materials, etc. After appropriate instruction from supervisor or site safety personnel, has ability to perform duties of fire watch and confined-space attendant. The Construction Worker is not expected to work independently and will generally work under the direct supervision of skilled construction workers, craftsmen, or site supervisors until they are competent to perform the tasks of a Mechanical Helper.

—

Mechanical Helper (General Labor)

Has some experience on construction worksites, and understands and has experience in the use of most basic hand tools and hand power tools and some heavy equipment. Knows how to properly use basic gasoline and air-powered tools including rock drills, jackhammers, rivet-busters, chainsaws, cut-off saws and others. Works effectively and efficiently at tasks, such as: shoveling, drilling, jack hammering, carrying, jobsite housekeeping, running errands, moving materials, etc. After appropriate instruction from supervisor or site safety personnel, has ability to perform duties of fire watch and confined-space attendant. Competent assistant to skilled craftsmen in a range of skills necessary for general heavy and commercial construction and learns the higher-level skills required to become a Millwright.

—

Structural Welder / Ironworker (Steel Building Erection, Welding, Fabrication)

—

Pipe Welder / Pipe Fitter

—

Millwright (Mill or Hydro-Turbine)

Has extensive experience on construction worksites, and thorough understanding and experience in the use of basic hand tools, portable power tools, and some heavy equipment. Ability to use a wide range of specialty tools, such as torque wrenches, torque multipliers, slug wrenches, porta-power units, Hillman rollers, hickey bars, steel wedges, hand-held grinders of all descriptions, precision measuring tools, and laser alignment tools to balance and align mechanical systems. The ability to read, understand, and interpret blueprints, as well as clearly relay that information and further instructions to other members of the construction crew. Under the supervision of a crane operator, journey-level craftsman, or crew foreman, conduct rigging operations routinely, competently, safely, and independently for materials and equipment for movement by hand or by on-site mobile crane, backhoe, forklift or other powered lifting device. Works with steel and other materials and must often combine the skills of several skilled trades in order to successfully fabricate industrial machinery or to assemble machines from prefabricated parts. Will lead less experienced crew members and perform any construction work tasks required to complete the job. When millwrighting tasks are not being performed, alternative duties are expected to be fulfilled, including that of a Mechanical Helper.

—

Mechanical Foreman (Crew or Task Leader)

A crew leader and skilled craftsman with extensive experience on mechanical construction worksites, and thorough understanding and experience in the use of basic hand tools and portable power tools and heavy equipment. Engaged with a variety of tasks performed on the construction site, from assisting subordinates to complete the work to managing a variety of crew sizes. The ability to read, understand, and interpret blueprints, as well as clearly relay that information and further instructions to other members of the construction crew. May help with project pre-planning and walkthroughs. Will be expected to be directly involved in set-up and completion of the assigned task(s), reporting information, ensuring site and crew safety, and maintain a positive relationship with the customer and general public. Will lead less experienced crew members and perform any construction work tasks required to complete the job. When foreman tasks are not being performed, alternative duties are expected to be fulfilled, including that of a Mechanical Helper.

—

General Benefits:

– Per Diem and Mileage, with your hotel booked and paid for by the company

– Company Sponsored Continued Trainings (equipment, safety, etc.)

– Paid Time Off (accrued each hour you work)

– 8 Paid Holidays, per year

—

Full Health Benefits Offering:

– Health and Dental Insurance

– HSA with Company Match

– Company Sponsored Health and Wellness Coaching

– Prescription Safety Glasses Reimbursement

– Complimentary Short- and Long-Term Disability

– Complimentary Life Insurance (with option for supplemental)

– 401(k), with a 3% contribution from Bancroft

—

If you’re interested in applying for any of these positions, please go to

Bancroft Contracting | Apply Online to submit your application.

Bancroft Contracting’s Welders and Fitters are utilized on industrial and commercial construction sites. The positions require heavy physical work under all environmental conditions. Good physical conditioning is important to success in the positions. Regardless of prior formal training or experience, an employee must demonstrate on the job, the ability to carry out or to quickly learn and competently execute, all essential functions of the position. These positions require travel within New England — either a valid driver’s license and reliable vehicle, or a practical alternative plan for getting to the jobsite, is a requirement of the job. A typical schedule is Monday through Friday, 6:30 a.m. to 5:00 p.m., with opportunities for additional work on weekends.

—

Positions Available

Structural Welder / Ironworker (Steel Building Erection, Welding, Fabrication)

Pipe Welder / Pipe Fitter

—

Instrument Fitter

—

General Benefits:

– Per Diem and Mileage, with your hotel booked and paid for by the company

– Company Sponsored Continued Trainings (equipment, safety, etc.)

– Paid Time Off (accrued each hour you work)

– 8 Paid Holidays, per year

—

Full Health Benefits Offering:

– Health and Dental Insurance

– HSA with Company Match

– Company Sponsored Health and Wellness Coaching

– Prescription Safety Glasses Reimbursement

– Complimentary Short- and Long-Term Disability

– Complimentary Life Insurance (with option for supplemental)

– 401(k), with a 3% contribution from Bancroft

—

If you’re interested in applying for this position, please go to

Bancroft Contracting | Apply Online to submit your application.

Bancroft Contracting’s Civil Trades are performed on industrial and commercial construction sites. The positions require heavy physical work under all environmental conditions. Good physical conditioning is important to success in the positions. Regardless of prior formal training or experience, an employee must demonstrate on the job, the ability to carry out or to quickly learn and competently execute, all essential functions of their position. These positions require travel within New England — either a valid driver’s license and reliable vehicle, or a practical alternative plan for getting to the jobsite, is a requirement of the job. A typical schedule is Monday through Friday, 6:30 a.m. to 5:00 p.m., with opportunities for additional work on weekends.

—

Positions Available

Construction Worker (Entry-Level)

Has limited to no experience on construction worksites, but understands and has some experience in the use of most basic hand tools and hand power tools. Quickly learns the use of basic gasoline and air-powered tools including rock drills, jackhammers, rivet-busters, chainsaws, cut-off saws and others. The Construction Worker learns to work effectively and efficiently at tasks such as shoveling, drilling, jack hammering, carrying, jobsite housekeeping, running errands, moving materials, etc. After appropriate instruction from supervisor or site safety personnel, has ability to perform duties of fire watch and confined-space attendant. The Construction Worker is not expected to work independently and will generally work under the direct supervision of skilled construction workers, craftsmen, or site supervisors until they are competent to perform the tasks of a Civil Helper.

—

Civil Helper (General Labor)

Has some experience on construction worksites, and understands and has experience in the use of most basic hand tools and hand power tools and some heavy equipment. Knows how to properly use basic gasoline and air-powered tools including rock drills, jackhammers, rivet-busters, chainsaws, cut-off saws and others. Works effectively and efficiently at tasks, such as: shoveling, drilling, jack hammering, carrying, jobsite housekeeping, running errands, moving materials, etc. After appropriate instruction from supervisor or site safety personnel, has ability to perform duties of fire watch and confined-space attendant. Competent assistant to skilled craftsmen in a range of skills necessary for general heavy and commercial construction and learns the higher-level skills required to become a Carpenter.

—

Carpenter (Carpentry, Re-bar, and Concrete Placement & Finishing)

Has significant experience on construction worksites, and understands and has experience in the use of basic hand tools and portable power tools and some heavy equipment. The ability to read, understand, and interpret blueprints, as well as clearly relay that information and further instructions to other members of the construction crew. Under the supervision of a crane operator, journey-level craftsman, or crew foreman, conduct rigging operations routinely, competently, safely, and independently for materials and equipment for movement by hand or by on-site mobile crane, backhoe, forklift or other powered lifting device. Assists in the construction of cast-in-place concrete forms, using pre-manufactured concrete form systems or stick-building forms on site. Assists in building re-bar structures, as required, for reinforcement of cast-in-place concrete. Places concrete in forms according to supplier recommendations and job specifications. Rough-finishes cast-in-place concrete structures where final finished appearance is non-critical. Will lead less experienced crew members as the demands of production require. When carpentry tasks are not being performed, alternative duties are expected to be fulfilled, including that of a Civil Helper.

—

Structural Welder / Ironworker (Steel Building Erection, Welding, Fabrication)

—

Civil Foreman (Crew or Task Leader)

A crew leader and skilled craftsman with significant experience on civil construction worksites, and thorough understanding and experience in the use of basic hand tools and portable power tools and heavy equipment. Engaged with a variety of tasks performed on the construction site, from assisting subordinates to complete the work to managing a variety of crew sizes. The ability to read, understand, and interpret blueprints, as well as clearly relay that information and further instructions to other members of the construction crew. May help with project pre-planning and walkthroughs. Will be expected to be directly involved in set-up and completion of the assigned task(s), reporting information, ensuring site and crew safety, and maintain a positive relationship with the customer and general public. Will lead less experienced crew members and perform any construction work tasks required to complete the job. When foreman tasks are not being performed, alternative duties are expected to be fulfilled, including that of a Civil Helper.

—

General Benefits:

– Per Diem and Mileage, with your hotel booked and paid for by the company

– Company Sponsored Continued Trainings (equipment, safety, etc.)

– Paid Time Off (accrued each hour you work)

– 8 Paid Holidays, per year

—

Full Health Benefits Offering:

– Health and Dental Insurance

– HSA with Company Match

– Company Sponsored Health and Wellness Coaching

– Prescription Safety Glasses Reimbursement

– Complimentary Short- and Long-Term Disability

– Complimentary Life Insurance (with option for supplemental)

– 401(k), with a 3% contribution from Bancroft

—

If you’re interested in applying for any of these positions, please go to

Bancroft Contracting | Apply Online to submit your application.

Sorry, no result found. Try another keyword